SUS304 / SS316 L Mixing tank

SUS304 / SS316 L Mixing tank

① Machine introduction

Stainless steel mixing tank can also be called water phase tank, widely used in coating, medicine, building materials, chemical industry, pigments, resins, food, scientific research and other industries. The equipment can be made of carbon steel, stainless steel and other materials according to the process requirements of the user's products, as well as set up heating and cooling devices to meet different processes and production needs.

The heating forms include electric heating with clip sleeve and coil heating. The equipment has reasonable structure, advanced technology, durable service, simple operation and convenient operation. It is an ideal chemical equipment with low investment, fast production and high profit.

② Structure of tank

Stainless steel mixing tank is composed of mixing tank body, mixing tank cover, mixer, support, transmission device, shaft seal device, etc.

The stainless steel agitator tank can be connected with the tank cover by flange sealing or welding. The tank body and the tank cover can be opened according to the process requirements, such as feed, discharge, observation, temperature measurement, pressure measurement, steam fractionation, safe venting and other process pipe holes.

Stainless steel tank cover is equipped with a transmission device (motor or reducer), driven by drive shaft agitator in the tank.

Shaft seal device can adopt machine seal or packing, labyrinth seal and other forms (specific requirements are determined according to customers).

Mixer can be equipped with slurry type, anchor type, frame type, screw type and other forms.

③ Processing device

Generally, the unit of use depends on whether the material is heated or dried or cooled. Within the scope of the custom, temperature should be below 230 ℃, using pressure below 0.1 Mpa. The heating method may depend on the production conditions of the unit in use. Heating methods include heating oil and other medium circulation and direct electric heating. The medium circulation, such as hot oil, is the transfer circulation of heat conducting oil through the hot oil pump after the heat conduction oil is heated to a certain temperature in another heating tank. Direct heating is to install electric heating tube directly on the jacket so that the heat conducting oil can be heated to the required temperature (the temperature can be adjusted according to the actual situation). The cooling cycle use water to circulate in and out of the jacket so that the material does not form agglomeration or stickiness at a certain temperature.

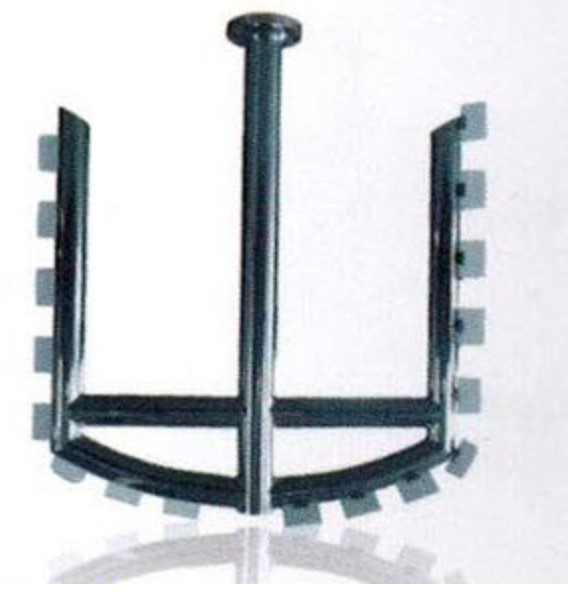

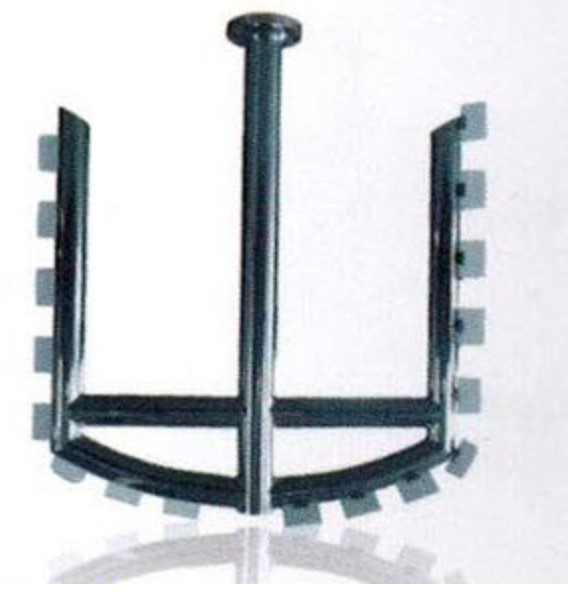

④ Mixer form show :

|

|

|

|

|

Paddle mixer |

Anchored mixer |

Frame mixer |

Scraper mixer |

⑤ Mixer form introduction :

Ø Paddle mixer : Suitable for low viscosity liquid.such as milk,beverage,beer etc.

Ø Anchored Mixer : Suitable for stirring medium viscosity material

Ø Frame mixer : Suitable for stirring porridge-type material

Ø Scraper mixer : Petrochemicals, pesticides, fine chemicals, high polymer, pharmaceutical, food, cosmetics, dyes, paints, water treatment and other industries

Ø Emusifier : Emulsion is a mixture of two or more liquids that are normally immiscible (unmixable or unblendable). Emulsions are part of a more general class of two-phase systems of matter called colloids.Food (dairy) products, beverage, pharmaceutical, chemical and other industries, the material for mixing, emulsifying effect .

Ø Scattered disk : The jagged coatings up and down ,to finish a high-speed shear, impact, crushing, dispersion to paints, dry, solid - liquid materials etc, in order to achieve rapid mixing, dissolving, dispersing, refined state.

Ø Magnetic agitation : Magnetic stirrer or magnetic mixer is a laboratory device that employs a rotating magnetic field to cause a stir bar (also called "flea") immersed in a liquid to spin very quickly, thus stirring it. The rotating field may be created either by a rotating magnet or a set of stationary electromagnets, placed beneath the vessel with the liquid.Pharmaceutical, fine chemicals, cosmetics, biotechnology and other industries

⑥ Function introduction :

Ø Heating : Electric /steam / coil tube heating

Ø Cooling : Cooling water / ice water /

Ø Pressure : Vacuum / normal pressure working environment

Ø Fitting : manhole,aseptic breather,thermometer,CIP spray ball,liquid level meterladder etc.

⑦ Machine shows :

Address:Shanghai China

Address:Shanghai China Hotline:18616504539

Hotline:18616504539  Email: antonia@vanoo.net

Email: antonia@vanoo.net